TECHNOLOGY EXPERTISE

-

LET'S THINKTOGETHERWe truly believe that working together as people, without the labels of

LET'S THINKTOGETHERWe truly believe that working together as people, without the labels of

"customer-supplier" allows us to add experience and knowledge to offer solutions

that improve the environment of people and increase the competitiveness

of the companies.

CONVERTING EXPERTISE

TECHNOLOGY EXPERTISE

CONVERTING EXPERTISE

INNOVATE SOLUTIONS

CAPABILITIES

ROLLS PREPARATION

Laminating, slitting, sheeting.

TRANSFORMATION

Die Cutting

FINISHED GOODS PREPARATION

Light assembly | Kitting | Packaging

ROLLS PREPARATION

SPOOL WOUND ROLLS

SPOOLWOUND

Rolls on spool wound format to minimize roll change overs and safe space.

ROLLS PREPARATION

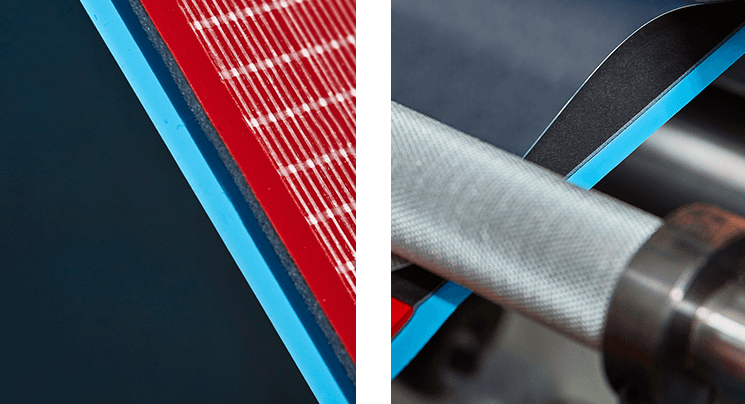

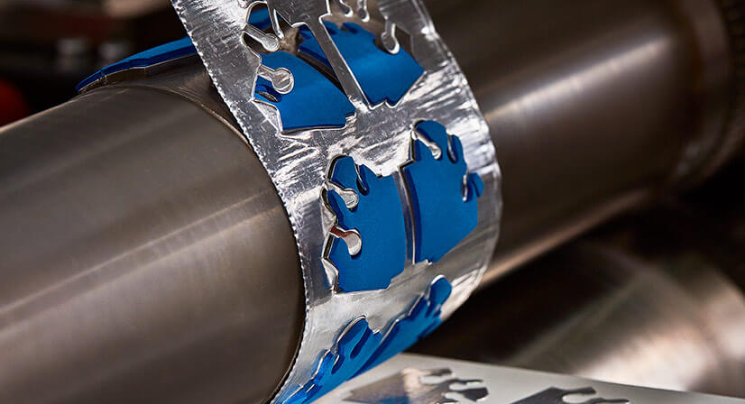

LAMINATING

LAMINATING

Bonding two or more flexible materials together by applying dynamic pressure.

At least one material is a pressure/temperature sensitive activated adhesive.

FINISHED GOODS PREPARATION

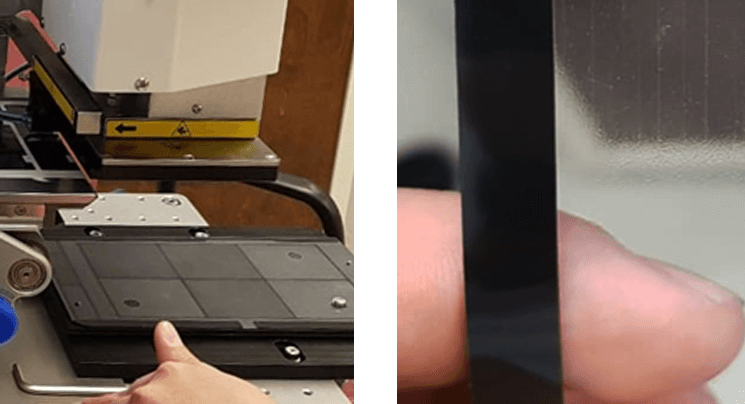

LIGHT ASSEMBLY

(ADHESIVE COMPONENT PLACEMENT)

Accurate placement of die cuts onto other die-cut or sheet of flexible or rigid material.

Typically the die cuts come in rolls to be picked-up and placed on the substrate.

TRANSFORMATION

DIE-CUTTING

(DIE CUTTING)

Cutting of a flexible material into a desired specific shape/geometry.

Typically the flexible material comes in pre-cut rolls or sheets.

Common die-cutting methods. Rotary, Flat-bed, CAD system (knife or laser plotters).

ROLLS PREPARATION

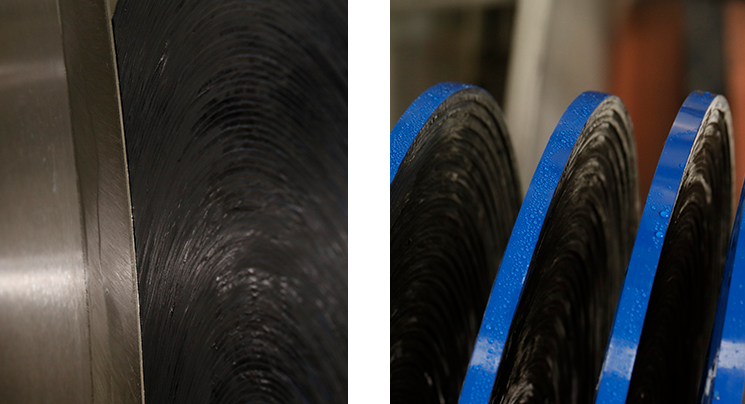

SLITTING

SLITTING

Cutting of a flexible material master roll into narrow separated (split) cuts.

Common slitting methods: razor slitting, shear slitting, lathe (baloney) slitting.

Capability to cut rolls to non-std narrow widths.

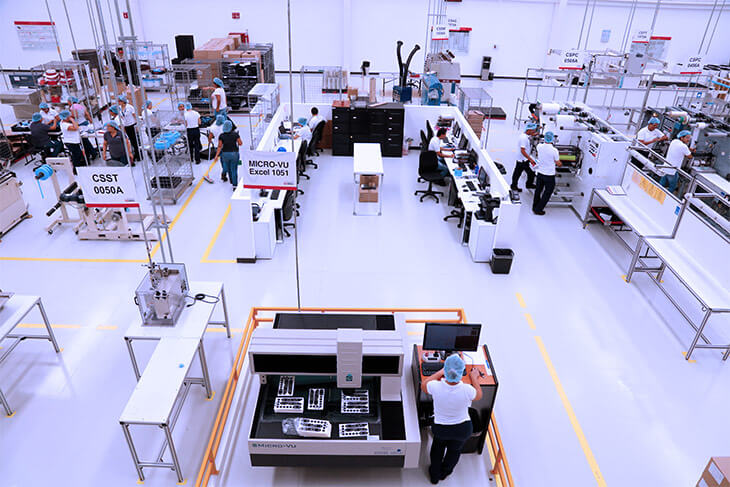

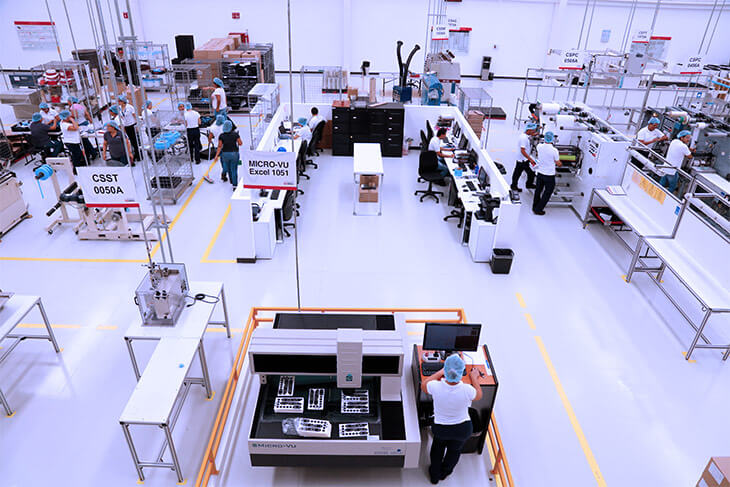

OUR PLANT

MANUFACTURING TACTICS FOR PRODUCTIVITY

OUR PLANT

MULTI SHEETS PER CYCLE

Increase output per rev/stroke.

(Step 5 Methodology)

OFF THE PRESS PREPARATION OF ROLLS

Reduces change over time, increases plant availability.

(Step 5 Methodology;SMED)

MULTIPLE QUALIFIED OPERATORS

Multi-habilidades, flexibilidad. (Programa ILU)

RAW MATERIAL YIELD

Effective nesting maximizes use of materials from design. (Nesting Method)

FULL BANDWIDTH UTILIZATION

fewer operations, larger pieces, increases output per rev. (From 7” to 20” wide)

OUR PLANT

MULTI SHEETS PER CYCLE

Increase output per rev/stroke.

(Step 5 Methodology)

OFF THE PRESS PREPARATION OF ROLLS

Reduces change over time, increases plant availability.

(Step 5 Methodology;SMED)

MULTIPLE QUALIFIED OPERATORS

Multi-habilidades, flexibilidad. (Programa ILU)

RAW MATERIAL YIELD

Effective nesting maximizes use of materials from design. (Nesting Method)

FULL BANDWIDTH UTILIZATION

fewer operations, larger pieces, increases output per rev. (From 7” to 20” wide)